Fume extraction systems for laser, plasma and flame cutting tables

Work such as welding, plasma cutting and thermal metal-cutting processes generates fumes, gases and particles that are classified as hazardous substances. These extremely fine particles can be inhaled deep into the alveolar ducts of the lungs. Some metals lead to the formation of substances that can cause serious respiratory diseases and even cancer.

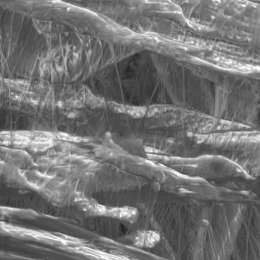

The optimum solution for such applications is the use of filter panels with a laminated ePTFE membrane coating. Our ePTFE membrane filter panels comply with dust classes H12 and H13 in accordance with EN 1822 under the applicable filter surface load. This quality is tested and certified by an independent institute. Other filter media do not achieve this level of filtration performance! When purchasing your filter cartridges, it is, therefore, essential to choose the best quality available for the protection of your workforce and the environment.

Pre-coating powder for filter panels

Welding fumes can sometimes also contain sticky particles. When installing new filter cartridges, it is, therefore, helpful to coat them with a layer of special protective powder before the dust comes into contact with the filter medium. This pre-coating (application of a separating layer between the filter medium and the dust cake) increases the service life of the filter panels considerably and greatly improves cleaning efficiency.